A rice mill plant is an agricultural processing facility that is specifically designed for the purpose of milling and processing rice grains into various rice products.

The primary objective of a rice mill plant is to remove the outer husk, bran, and germ layers from the rice grain, resulting in polished white rice that is ready for consumption.

Rice mill plants can vary in size and capacity, ranging from small-scale mills for local consumption to large-scale industrial plants that produce rice on a commercial scale. The specific equipment and processes used may also vary depending on the desired end products and the level of automation in the plant.

Cleaning and Preparatory Stage: The harvested rice paddy undergoes cleaning and preparatory processes to remove impurities such as stones, dust, and other foreign materials. This stage usually involves the use of various cleaning equipment like vibrating screens, magnetic separators, and destoners.

Husking: In this stage, the outer husk or hull of the rice grain is removed. Traditionally, this process was done manually using mortar and pestle, but modern rice mill plants employ mechanical husking machines, known as hullers or shellers, to remove the husk.

Separation of Bran and Germ: After husking, the rice grains still have bran and germ layers attached. The bran and germ need to be separated from the white rice. This process is usually accomplished through the use of a machine called a whitener or a bran separator.

Polishing: Once the bran and germ layers are removed, the rice grains are polished to give them a shiny appearance. Polishing is carried out using a machine called a polisher, which removes any remaining bran particles from the surface of the rice grains.

Sorting and Grading: The polished rice is then sorted and graded based on size, shape, and quality. This process helps to remove any remaining impurities, damaged or discolored grains, and ensures uniformity in the final product. Optical sorting machines are often used for this purpose.

Packaging and Storage: The final step involves packaging the processed rice into bags or containers, ready for distribution and sale. Proper storage facilities with controlled temperature and humidity are essential to maintain the quality and shelf life of the rice.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

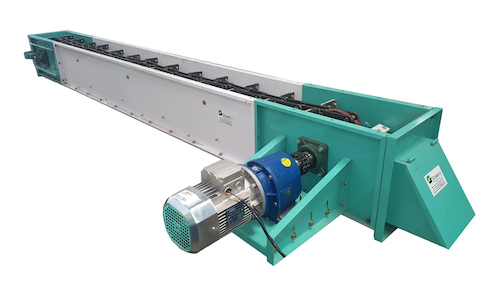

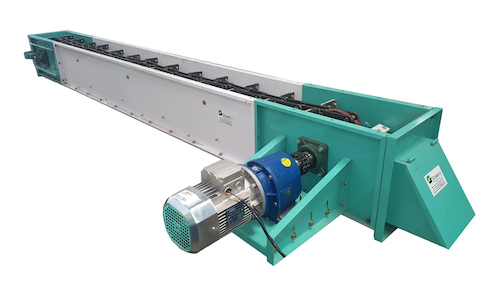

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

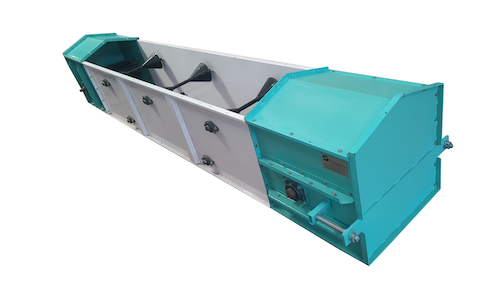

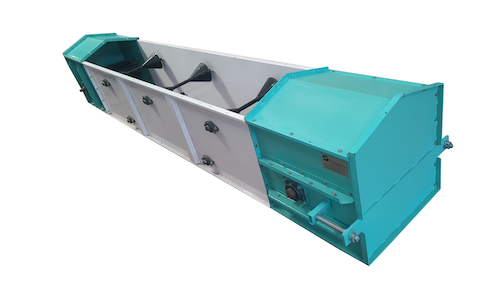

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.