A dust cyclone, also known as a cyclone separator or cyclone dust collector, is a device used to remove dust and particulate matter from an air or gas stream. It is commonly employed in industrial settings, including plant facilities, to improve air quality, protect equipment, and ensure a safe and healthy working environment.

It's important to note that the efficiency and performance of a dust cyclone depend on factors such as airflow rate, particle size distribution, and the specific characteristics of the dust being collected. Proper sizing, installation, and regular maintenance are crucial for optimal dust collection efficiency and overall system performance.

Inlet and Tangential Entry: The contaminated air or gas enters the dust cyclone through an inlet, usually tangentially. The tangential entry causes the airstream to rotate rapidly within the cylindrical or conical-shaped cyclone body.

Centrifugal Force: As the airstream rotates, centrifugal force pushes the heavier dust particles towards the cyclone's outer walls. The particles move downward due to gravity and accumulate in a lower collection area called the dust hopper.

Clean Air Outlet: The cleaner air, with smaller particles or reduced dust concentration, moves upward toward the center of the cyclone and exits through a clean air outlet located at the top of the cyclone.

Dust Collection and Disposal: The collected dust in the dust hopper can be periodically emptied or disposed of, depending on the specific design of the dust cyclone. Some systems may incorporate mechanisms for automatic dust discharge, while others may require manual cleaning or maintenance.

High Efficiency: Dust cyclones can achieve high separation efficiencies, depending on their design and operating conditions. They can effectively remove a significant portion of the dust and particulate matter from the air or gas stream.

Simple and Robust Design: Dust cyclones have a relatively simple construction, consisting of a cyclone body, inlet, outlet, and dust hopper. This design makes them robust, reliable, and suitable for a wide range of industrial applications.

Low Maintenance: Dust cyclones require minimal maintenance compared to other dust collection systems. They have no moving parts and do not rely on filter media that may require regular replacement or cleaning.

Cost-Effective: Dust cyclones are often considered a cost-effective solution for dust collection. They have lower initial costs compared to some other dust collection systems and can provide efficient dust separation for many industrial processes.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

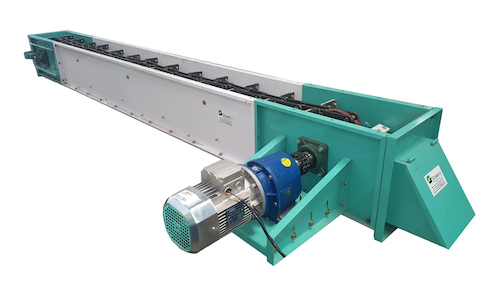

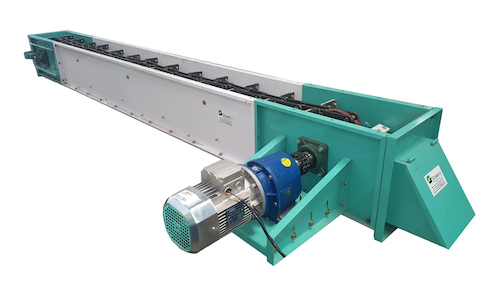

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

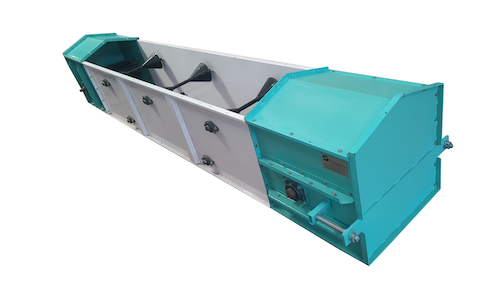

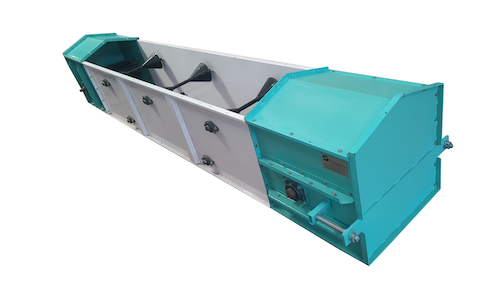

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.