An air venturi for husk conveying is likely a component in a pneumatic conveying system used to transport husk or similar materials. Venturi systems use a constriction to create a pressure difference, allowing air to move the material through pipes. This technology is often employed in industries like agriculture for handling husks or other particulate matter efficiently. For detailed information, consulting manufacturers or specialized resources in pneumatic conveying systems would be beneficial.

An air venturi refers to a device that utilizes the Venturi effect to create a controlled flow of air or another fluid. The Venturi effect is a phenomenon in fluid dynamics where the pressure of a fluid decreases as it flows through a constricted section of a pipe. This reduction in pressure is due to the increase in the fluid's velocity.

Constricted Tube or Nozzle: The key component of an air venturi is a constricted tube or nozzle. This narrowing of the tube accelerates the fluid (air) passing through it.

High-Pressure Inlet: The fluid enters the venturi at a higher pressure and lower velocity.

Constriction (Throat): This is the narrowest part of the venturi where the fluid velocity increases, and pressure decreases.

Diverging Section: Following the constriction, the tube gradually widens, causing the fluid velocity to decrease and the pressure to increase. This section helps control the flow and pressure.

The primary application of air venturis is to create suction or vacuum. When high-pressure air is forced through the constricted tube, a low-pressure area is generated at the throat of the venturi. This low-pressure zone can be utilized for various purposes, such as suction in vacuum systems, fuel or air mixing in combustion processes, or material conveying in industrial applications.

In industrial settings, air venturis can be employed in pneumatic conveying systems, where they assist in transporting materials (such as powders or granular substances) through pipelines using a stream of air. They are also used in applications like aspirators, where they draw in air or other gases for mixing or creating air flow. The efficiency and performance of an air venturi depend on the design of the constriction, the pressure of the incoming fluid, and the intended application.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

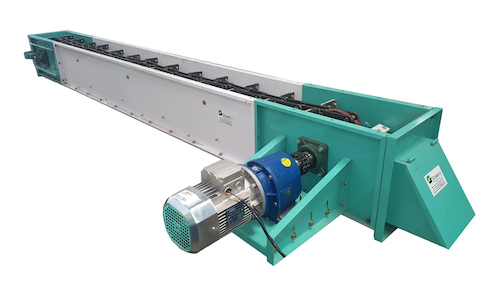

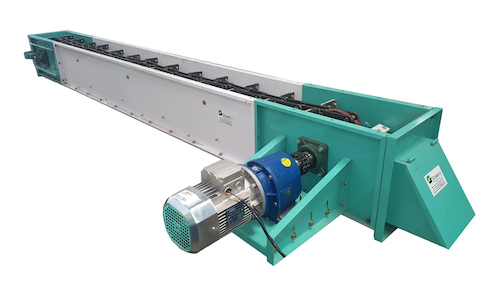

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

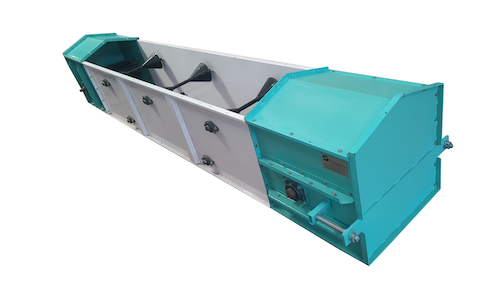

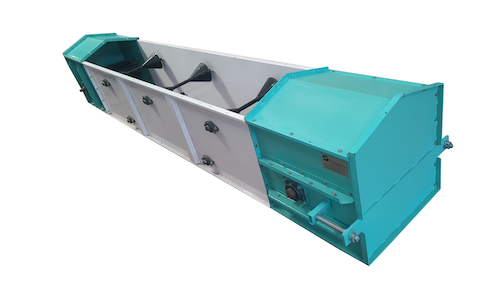

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.