The machine helps ensure uniformity in the dal product and allows for consistent packaging and distribution.

Here is an overview of how a typical dal grader machine works:

Feeding:The dal grains are fed into the grader machine through a hopper or conveyor system. The feeding mechanism ensures a continuous flow of dal grains for grading.

Grading Mechanism:The dal grader machine consists of a series of vibrating screens or sieves with different-sized perforations or mesh sizes. The dal grains pass through these screens, allowing grains of specific sizes to pass through while retaining larger or smaller grains.

Size Separation:As the dal grains move along the vibrating screens, they are separated into different size fractions based on the mesh size of the screens. Each screen or sieve allows dal grains falling within a specific size range to pass through.

Sorting and Grading:The dal grader machine may incorporate additional mechanisms for further sorting and grading based on other factors like shape and quality. Optical sensors, air jets, or other mechanisms may be used to detect and separate grains with irregular shapes or blemishes.

Collection and Packaging:The sorted and graded dal grains are discharged from the grader machine through different outlets or collection points corresponding to each grade or size fraction. The dal grains are then collected for further processing, packaging, or distribution.

It's important to note that the specific design and features of a dal grader machine can vary depending on the manufacturer and the desired capacity and precision of grading. Some machines may include adjustable settings, multiple screens, or additional mechanisms to optimize the grading process for different types and sizes of dal grains.

The use of a dal grader machine ensures uniformity and consistency in the dal product by separating grains into different size fractions and possibly sorting based on other criteria. This allows for efficient packaging, quality control, and meeting specific market requirements for dal products.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

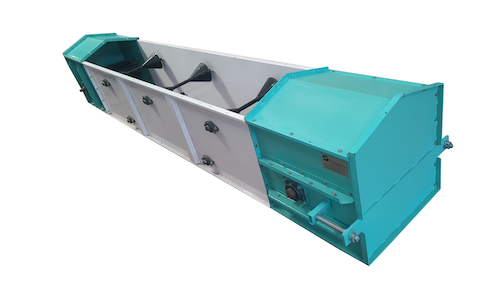

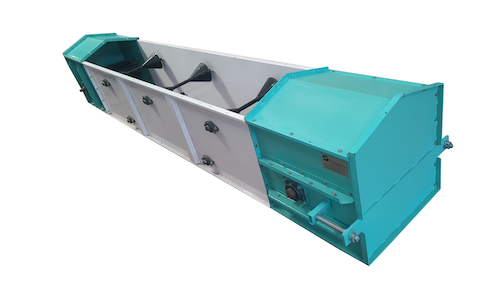

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

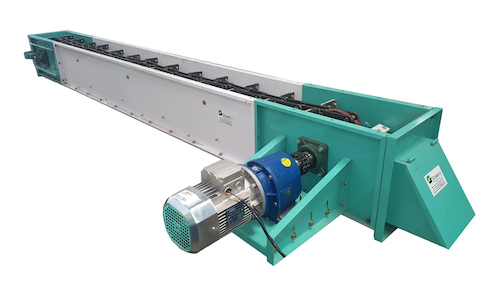

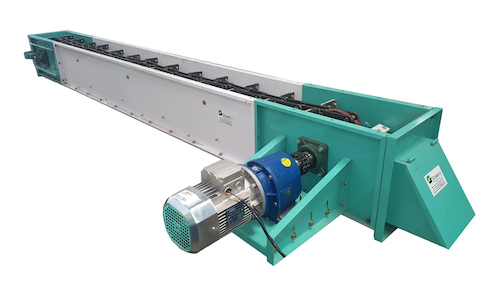

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.