A pneumatic slide gate is often used as a component of the material handling system to control the flow of bulk materials, such as grains, powders, or granular products.

Pneumatic slide gates in mill plants offer advantages such as precise control, automation capabilities, and quick response times. They are typically constructed using sturdy materials like steel or other robust alloys to withstand the abrasive nature of the handled materials and the demanding mill environment.

Material Flow Control: Pneumatic slide gates are installed at various points in the material handling system to regulate the flow of bulk materials. They can be positioned at the discharge points of conveyors, hoppers, chutes, or silos to control the release or redirection of materials during processing or storage.

Batching and Mixing: In mill plants that involve batching or mixing processes, pneumatic slide gates are used to control the precise amount of materials entering the mixing equipment. They allow operators to open or close the gate using pneumatic pressure, controlling the flow rate and ensuring accurate ingredient proportions.

Process Isolation: Pneumatic slide gates are employed to isolate different stages of the milling process. They help separate and redirect materials to specific equipment or process units, ensuring proper sequencing and preventing cross-contamination.

Maintenance and Equipment Access: Pneumatic slide gates can be used to temporarily block material flow during equipment maintenance or repair. By closing the gate using pneumatic pressure, operators can isolate a section of the processing line or create a safe working area.

Automated Material Handling: Pneumatic slide gates can be integrated into automated material handling systems in a mill plant. They can be controlled by a central control system or programmable logic controller (PLC) to facilitate precise and efficient material flow management.

Position Sensors and Control Systems: Pneumatic slide gates in mill plants can be equipped with position sensors to detect the gate's open or closed position. These sensors provide feedback to the control system, allowing for accurate monitoring and control of material flow.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

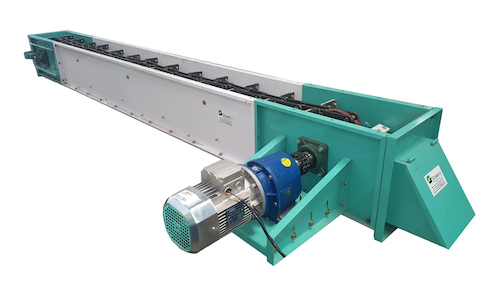

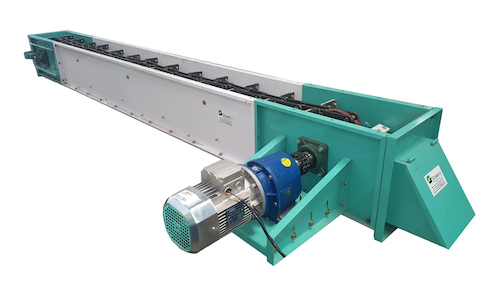

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

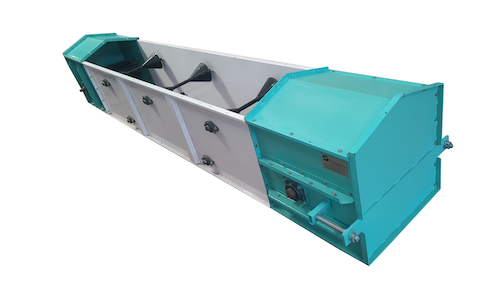

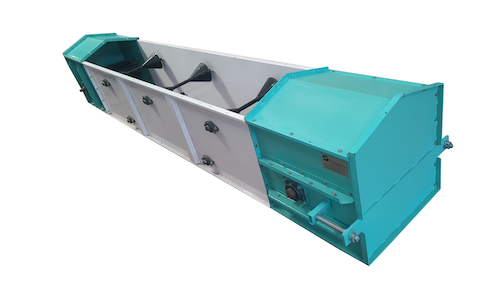

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.