Aspirational ducting typically refers to the ducting system used for aspiration or ventilation purposes. In mill plants, aspiration is commonly employed to remove dust, chaff, or other particulate matter generated during milling or processing operations.

The aspiration ducting system helps capture and transport these airborne particles away from the milling equipment and surrounding areas. Proper design, installation, and maintenance of aspirational ducting systems are essential to ensure effective dust and particle control in mill plants. The ducting should be properly sized, sealed, and free from leaks to maximize the capture and transport of airborne particles.

Capture Points: Aspirational ducting is strategically positioned near the milling or processing equipment to capture airborne particles as they are generated. These capture points are typically equipped with hoods, enclosures, or other devices designed to efficiently collect the airborne particles.

Ductwork: The captured particles are then transported through the aspirational ducting system using ductwork. The ductwork consists of a network of pipes or channels that connect the capture points to a central collection system, such as a dust collector or cyclone separator.

Airflow and Suction: To create airflow and suction, an aspirator or fan is typically installed in the aspirational ducting system. The fan generates negative pressure within the ductwork, drawing the airborne particles towards the collection system.

Filters and Separators: In some cases, filters or separators may be integrated into the aspirational ducting system to remove finer particles or impurities before they reach the collection system. These filters help improve air quality and prevent clogging or damage to the collection equipment.

Exhaust or Discharge: The collected particles are separated from the air stream in the collection system, while the clean air is typically exhausted or discharged outside the mill plant or further treated if required.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

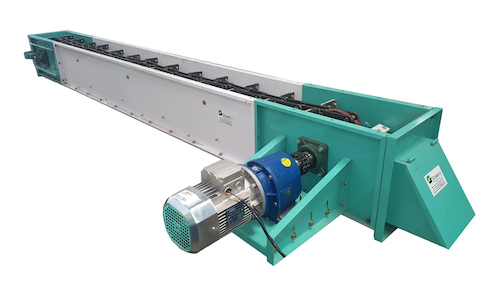

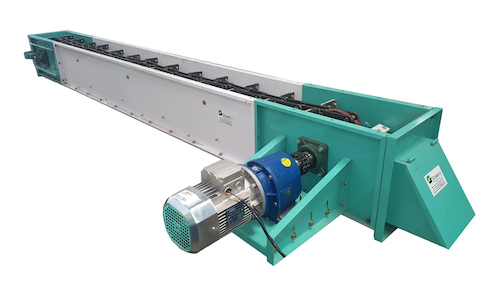

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

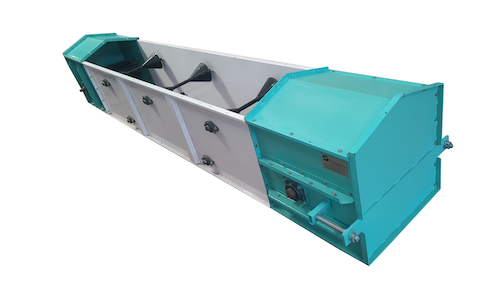

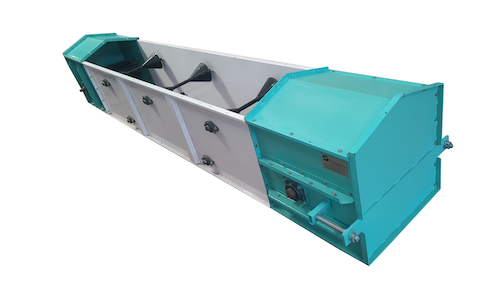

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.

We always mind core values and quality.

Steelco

A bucket elevator is a mechanical device used to vertically lift the any kind of food grain without any grain damage during the lift.

Robust

Indented Cylinder machine is used to very precise separation of the whole rice and broken rice according to length.

Accurate

A Vibro Classifier in various industries to separate or classify materials based on their size or particle.

Clean Grain

A destoner is a machine or device used in various industries, such as agriculture, food processing, to remove stones, rocks, and other heavy impurities from a material stream.

Deep Filter

Pulse cleaning machine is used to separate foreign materials, such as stones, dirt, chaff, sticks, and other debris, from the pulse crops.

Heavy

A chain conveyor is a type of mechanical conveying system that utilizes a continuous chain to transport bulk materials or products horizontally, vertically, or at an incline.

Clean Grain

A belt conveyor is a common type of mechanical conveying system used to transport bulk materials or products horizontally or at an inclined angle.

Screw

A screw conveyor is a type of mechanical conveying system that uses a rotating screw-shaped auger to transport bulk materials horizontally, vertically, or at an incline.

Plant

A Dust Cyclone is designed to separate solid particles from gas or air streams, helping to improve air quality, and comply with environmental regulations.

Clean Grain

A rice length grader machine is a machine used in the rice processing industry to separate rice grains based on their length.

Deep Filter

A rice bran centrifugal separator is a type of machinery used in the rice bran oil extraction process. Rice bran is the outer layer of rice grains.

Heavy

A rice husk rotary airlock, valve or feeder, is a specialized device used in pneumatic conveying systems to control the flow of rice husk or other similar materials.